cnc machine language Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where . In January, United Metal Fabricators, Inc. rebranded as UMF Medical, and quickly .

0 · manual cnc programming for beginners

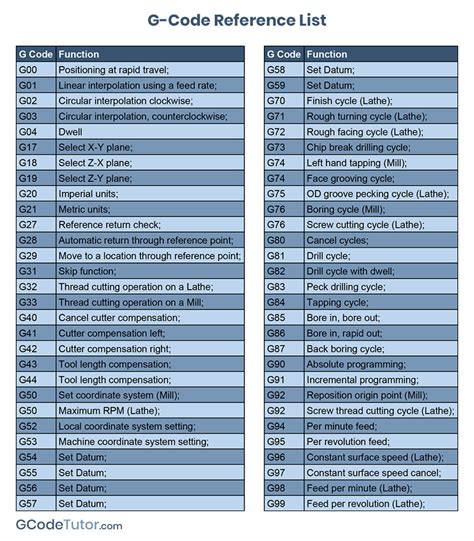

1 · list of cnc g codes

2 · different types of cnc programming

3 · cnc turning g code list

4 · cnc programming languages list

5 · cnc machine programming and operation

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

• Ural-4320 with headlights in bumper (civilian version since the mid-1990s)• Ural-4320 with headlights in wings (civilian and military versions before the mid-1990s) See more

manual cnc programming for beginners

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or . For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how .

list of cnc g codes

Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where .

Our guide delves into G Code for geometric moves and M Code for machine functions, essential for CNC programming. CNC machines rely on G Code and M Code, foundational programming languages. G Code controls .

In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete .

G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a .

G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M . G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’. G-code guides the CNC machine’s actions by combining .

G-code is the simple programming language for CNC machines. It consists of lines of code that are organized in blocks. Each block controls one CNC machining operation, such as a cutting operation with a specific tool. .

different types of cnc programming

G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants. For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how it’s made, and how to read it will make that decision easier. Our guide delves into G Code for geometric moves and M Code for machine functions, essential for CNC programming. CNC machines rely on G Code and M Code, foundational programming languages. G Code controls movement, while M Code manages machine functions. G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes, and 3D printers. These CNC machines receive their instructions using a programming language called g-code. G-code is the simple programming language for CNC machines. It consists of lines of code that are organized in blocks. Each block controls one CNC machining operation, such as a cutting operation with a specific tool. G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe.

G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’. G-code guides the CNC machine’s actions by combining instructions readable by the microcontroller. This simple programming language requires no intricate logic or mathematical skills.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications.G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants. For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how it’s made, and how to read it will make that decision easier. Our guide delves into G Code for geometric moves and M Code for machine functions, essential for CNC programming. CNC machines rely on G Code and M Code, foundational programming languages. G Code controls movement, while M Code manages machine functions.

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often. CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes, and 3D printers. These CNC machines receive their instructions using a programming language called g-code.

G-code is the simple programming language for CNC machines. It consists of lines of code that are organized in blocks. Each block controls one CNC machining operation, such as a cutting operation with a specific tool. G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe. G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’. G-code guides the CNC machine’s actions by combining instructions readable by the microcontroller. This simple programming language requires no intricate logic or mathematical skills.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

lowes kobalt metal plate for tru k tool box

cnc turning g code list

cnc programming languages list

cnc machine programming and operation

联合金属有限公司 united sheet metal works inc. 坐落于纽约市法拉盛皇后区,是一家有着10年历史的钢材制作和建筑工厂。 我们拥有从生产、质检、销售和售后的一体化团队。 为您提供优质的服务

cnc machine language|cnc machine programming and operation